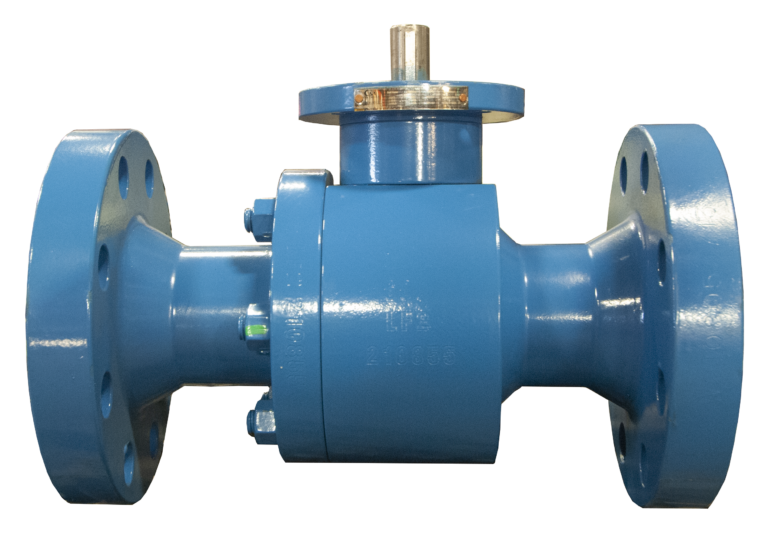

What is a Floating Ball Valve?

A floating ball valve is a type of quarter-turn valve that uses a ball with a central bore to control the flow of fluid or gas through a pipeline. The ball is not fixed or supported by a trunnion; instead, it is held in place by two valve seats and floats slightly downstream against the seat to create a seal when closed. This design makes it ideal for low- to medium-pressure applications and ensures tight sealing performance.

Key Features of Floating Ball Valves

- Simple Design: With fewer components than trunnion-mounted ball valves, floating ball valves are easier to maintain and install.

- Tight Shut-off: The floating design allows the ball to press against the downstream seat for a reliable seal, even under low pressure.

- Quarter-turn Operation: Requires only a 90-degree rotation to fully open or close the valve.

- Blow-out Proof Stem: Designed to prevent the stem from being ejected in high-pressure scenarios.

Working Principle

When the valve handle is turned, the ball rotates 90 degrees, allowing or blocking flow through the bore. In the closed position, the fluid pressure forces the ball downstream against the seat, forming a tight seal. In the open position, the bore aligns with the pipeline, allowing free flow.

Materials Used

Floating ball valves are manufactured from various materials based on their application. Common options include:

- Stainless Steel

- Carbon Steel

- Brass

- PVC or CPVC for chemical or water systems

Types of Floating Ball Valves

- Two-piece Body: Composed of two main pieces, easy to service and cost-effective.

- Three-piece Body: Allows quick maintenance without removing the valve from the pipeline.

- Top Entry: Enables internal inspection and maintenance from the top side.

Applications of Floating Ball Valves

Floating ball valves are suitable for a wide range of general and industrial applications:

- Water Treatment: Used for water flow control in municipal and industrial systems.

- Oil and Gas: Suitable for upstream, midstream, and downstream applications with moderate pressure.

- Chemical Processing: Controls aggressive fluids safely.

- HVAC Systems: Regulates water and steam flow in heating and cooling systems.

- Food and Beverage Industry: Stainless steel valves maintain sanitary standards.

Advantages of Floating Ball Valves

- Compact and lightweight design

- Effective sealing even at low pressure

- Cost-effective compared to trunnion types

- Low maintenance requirements

Limitations

- Not suitable for high-pressure applications

- Wear on seats may increase with high flow rates or pressure differentials

Maintenance Tips

To ensure a long lifespan and reliable performance, consider these maintenance practices:

- Periodic inspection for wear or leakage

- Cleaning the valve internals if used in dirty or particulate-laden fluids

- Lubricating the stem and seals if required. Visit our website https://www.bjmvalves.com/ for details.

Conclusion

Floating ball valves offer an effective, simple, and cost-efficient solution for flow control in various applications. Their tight sealing, easy operation, and compact design make them especially ideal for low- to medium-pressure systems. Choosing the right material and configuration ensures long-term performance and reliability in demanding environments.